Welcome to the Eaton 78364 RDT manual, a comprehensive guide for the Eaton 78364-RDT-02 hydraulic pump. This manual provides detailed instructions for installation, maintenance, and troubleshooting, ensuring safe and efficient operation of the pump in various applications, including turf care, utility work, and mobile machinery. Designed for both users and technicians, it covers key features, technical specifications, and best practices to maximize performance and longevity of the equipment.

1.1 Overview of the Eaton 78364 RDT Hydraulic Pump

The Eaton 78364 RDT hydraulic pump, model number 78364-RDT-02, is a high-performance gear pump designed for various industrial and mobile applications. It is widely used in turf care, utility work, and small mobile machinery, offering reliable operation and durability; With displacements ranging from 20 cm³ to 49 cm³ (1.2 in³ to 3.0 in³), the pump supports continuously variable input speeds in both forward and reverse directions. Its robust design and compatibility with multiple systems make it a versatile choice for hydraulic power solutions. The pump is also noted for its ease of maintenance and compatibility with parts like PC40MR-2 and PC50MR-2.

1.2 Importance of the Manual for Users and Technicians

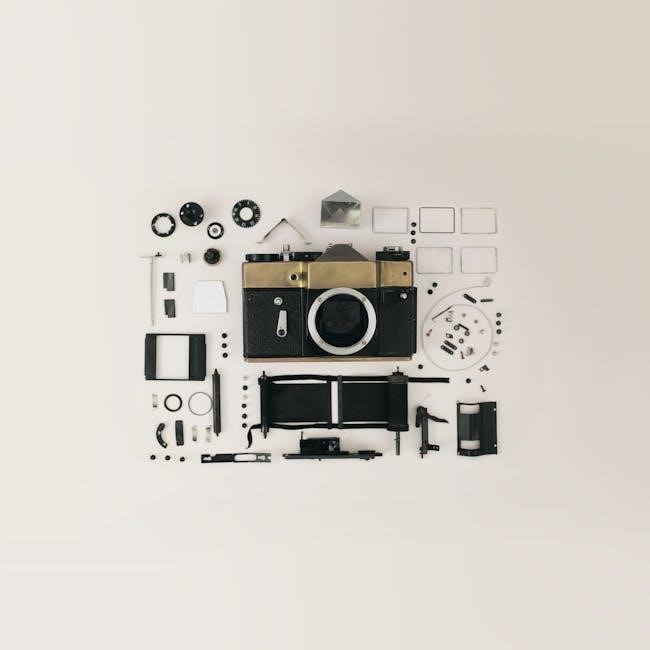

The Eaton 78364 RDT manual is a critical resource for both users and technicians, providing detailed guidance for safe and effective operation. It outlines operating parameters, installation steps, and maintenance procedures to ensure optimal performance. For users, the manual offers insights into proper usage, troubleshooting, and safety precautions. Technicians benefit from technical specifications, diagnostic tools, and repair guidelines. The manual also includes exploded views of components, enabling precise identification and replacement of parts. By adhering to the manual, users and technicians can maximize the pump’s lifespan, ensure compliance with safety standards, and maintain warranty validity. It is indispensable for efficient and reliable operation.

Product Specifications and Technical Details

The Eaton 78364-RDT-02 hydraulic pump features a flow rate of 10-50 GPM and pressure capacity up to 3000 PSI. It is lightweight, compact, and designed for high-performance applications, weighing approximately 45 lbs. The pump is compatible with mineral-based, synthetic, and bio hydraulic oils, ensuring versatility in various operating conditions.

2.1 Model Number and Type: Eaton 78364-RDT-02

The Eaton 78364-RDT-02 is a high-performance hydraulic pump designed for demanding applications. This model number specifies a particular configuration of the RDT series, known for its reliability and durability. The “RDT” designation indicates a rear-mounted, dual-stator pump with a through-drive capability, making it suitable for powering auxiliary hydraulic systems. The pump is built to withstand harsh operating conditions, featuring a robust construction and advanced sealing technology. Its compact design allows for easy integration into various machinery, while its high-efficiency operation ensures optimal performance. The Eaton 78364-RDT-02 is a popular choice for mobile equipment and industrial applications, offering consistent reliability and long service life.

2.2 Key Features of the Hydraulic Pump

The Eaton 78364-RDT-02 hydraulic pump is designed for high performance and versatility. It features a variable displacement design, allowing for precise flow control to meet varying application demands. The pump is known for its high efficiency, delivering optimal power while minimizing energy consumption. Its robust construction ensures durability and reliability in demanding environments. Additional features include advanced cooling systems to maintain consistent operating temperatures and a compact design for easy installation. The pump also incorporates noise-reduction technology, enhancing operational comfort. These features make the Eaton 78364-RDT-02 a reliable choice for applications requiring consistent hydraulic power and long-term durability.

2.3 Applications in Turf Care, Utility Work, and Mobile Machinery

The Eaton 78364-RDT hydraulic pump is widely used in turf care for powering equipment like mowers and sprayers, ensuring precise control and reliability. In utility work, it excels in applications such as digging and lifting, providing consistent power for demanding tasks. Additionally, the pump is ideal for mobile machinery, including skid-steer loaders and excavators, where its compact design and high efficiency enhance operational performance. Its versatility and durability make it a preferred choice across these industries, delivering dependable hydraulic power in diverse operational environments.

Installation Instructions and Guidelines

Follow the Eaton 78364-RDT manual for proper installation, ensuring system compatibility and safety. Prime the pump, check fluid levels, and test operation before full use.

3.1 Pre-Installation Requirements and Safety Precautions

Before installing the Eaton 78364 RDT hydraulic pump, ensure compatibility with existing systems and verify voltage, pressure, and flow rate requirements. Conduct a thorough inspection of the pump and connecting components for damage or wear. Ensure all safety protocols are followed, including de-energizing the system, wearing protective gear, and proper ventilation. Check fluid levels and viscosity, and use only approved hydraulic fluids. Review the manual for specific torque values and assembly instructions to prevent damage. Proper grounding and electrical connections are critical to avoid malfunction or injury. Ensure the installation area is clean and free from contaminants for optimal performance and longevity of the pump.

3.2 Step-by-Step Installation Process

The installation of the Eaton 78364 RDT hydraulic pump requires careful adherence to the following steps. Begin by mounting the pump securely to a stable surface, ensuring proper alignment with the drive system. Connect the hydraulic lines to the designated ports, making sure to match the inlet and outlet flows. Next, attach the electrical connections, referring to the manual for wiring specifications. Prime the pump to eliminate air pockets and ensure smooth operation. Finally, test the system at a low pressure setting to verify functionality before full operation. Always consult the manual for specific torque and alignment recommendations to guarantee optimal performance and safety.

3.3 Post-Installation Checks and Adjustments

After installing the Eaton 78364 RDT hydraulic pump, perform a series of checks to ensure proper functionality. Inspect all hydraulic lines and connections for leaks or damage. Verify that the pump is properly aligned with the drive system to prevent vibration and wear. Check the pressure settings and adjust them according to the manual’s specifications. Test the system at a low-pressure setting to ensure smooth operation. Monitor the hydraulic fluid level and condition, ensuring it meets the recommended specifications. Finally, record the installation details and schedule a follow-up maintenance check to ensure long-term performance and reliability.

Safety Precautions and Handling

- Always wear protective gear, including gloves and safety glasses, when handling the pump.

- Ensure the system is depressurized before performing any maintenance or repairs.

- Never touch hydraulic lines or components while the system is under pressure.

- Keep loose clothing and long hair tied back to avoid entanglement.

- Use proper lifting techniques to handle heavy components safely.

- Store the pump in a dry, well-ventilated area away from flammable materials.

4.1 General Safety Guidelines for Hydraulic Pumps

Adhering to safety guidelines is crucial when working with hydraulic pumps like the Eaton 78364 RDT to prevent accidents and ensure efficient operation. Always wear appropriate personal protective equipment (PPE), such as gloves and safety glasses, to protect against potential hazards. Ensure the system is depressurized before performing any maintenance or repairs to avoid sudden release of stored energy. Avoid contact with hot surfaces or moving parts, as they can cause severe burns or injuries. Properly lift heavy components to prevent strain or damage. Keep the work area clean and well-lit to minimize tripping hazards; Always follow the manufacturer’s instructions and safety protocols.

4.2 Safe Handling and Storage Practices

Proper handling and storage of the Eaton 78364 RDT hydraulic pump are essential to maintain its performance and longevity. When handling, use lifting straps or suitable tools to avoid physical strain or damage. Avoid dropping or exposing the pump to direct impact, as this could cause internal component failure. For storage, keep the pump in a clean, dry, and temperature-controlled environment. Use the original packaging if available to protect against dust and moisture. Ensure the pump is securely fastened to prevent movement during transport or storage. Regularly inspect stored units for signs of damage or corrosion before reinstalling or using them.

4.3 Emergency Procedures in Case of Malfunction

In case of a malfunction, immediately shut off the power supply to the Eaton 78364 RDT hydraulic pump to prevent further damage or injury. Relieve any built-up pressure in the system gradually to avoid sudden releases. Evacuate the area if there is a risk of fluid leakage or exposure to hazardous materials. Secure the pump and tag it as inoperative until professional inspection. Do not attempt repairs without proper training and tools. Always follow the manufacturer’s guidelines and consult the manual for specific emergency protocols. Contact Eaton’s technical support for assistance with repairs or replacement parts.

Maintenance and Repair Guidelines

Regular inspections, timely part replacements, and adherence to Eaton’s manual ensure optimal performance and extend the pump’s lifespan, minimizing downtime and maintaining warranty compliance effectively.

5.1 Routine Maintenance Schedule

Perform monthly checks on fluid levels, filter cleanliness, and hydraulic connections to ensure smooth operation. Inspect hoses and seals for wear or leaks annually. Replace hydraulic filters every 500 hours or as specified. Lubricate moving parts periodically to prevent friction. Check pressure settings and adjust if necessary. Refer to Eaton’s manual for detailed schedules and intervals. Adhere to these routines to maintain efficiency, prevent premature wear, and ensure compliance with manufacturer recommendations. Regular maintenance also helps identify potential issues early, reducing downtime and extending the pump’s lifespan. Always use genuine Eaton parts for replacements to guarantee optimal performance and warranty validity;

5.2 Troubleshooting Common Issues

Identify common issues like low flow rate, excessive noise, or fluid leaks. Check for clogged filters, worn pump components, or loose connections. Air in the system can cause noise; bleed the lines if necessary. Leaks may indicate damaged seals or faulty fittings. Consult the Eaton manual for diagnostic charts to pinpoint problems. Verify pressure settings and fluid levels regularly. Address overheating by ensuring proper cooling and fluid viscosity. For persistent issues, contact Eaton technical support or authorized service centers. Regular maintenance can prevent many of these problems, ensuring reliable performance and extending the pump’s service life. Always follow Eaton’s troubleshooting guidelines for accurate resolution.

5.3 Repair and Replacement of Parts

For repairs, always follow Eaton’s guidelines to ensure safety and compatibility. Disassemble the pump carefully, noting all components. Inspect for wear or damage, especially on seals, bearings, and pistons. Replace parts with genuine Eaton components to maintain performance. Reassemble in reverse order, ensuring all connections are secure. Check alignment and torque specifications. After reassembly, test the pump at low pressure to verify functionality. document all repairs for future reference. For complex issues, consult Eaton’s technical support or authorized service centers. Proper repair and replacement extend the pump’s lifespan and prevent future malfunctions, ensuring optimal performance and reliability in demanding applications.

Hydraulic Pump Components and Accessories

The Eaton 78364 RDT hydraulic pump consists of key components such as gears, pistons, and valves, ensuring efficient fluid flow and pressure management. Accessories include mounting brackets, filters, and control valves, enhancing performance and adaptability across various applications. Proper selection and installation of these components are critical for optimal functionality and longevity. Always use genuine Eaton parts to maintain warranty and performance standards. Accessories are designed to integrate seamlessly with the pump, offering reliability and durability in demanding operating conditions. Regular inspection and maintenance of these components are essential for sustained efficiency and system integrity.

6.1 Overview of Key Components

The Eaton 78364 RDT hydraulic pump features a robust design with essential components like gears, pistons, and control valves. These elements work together to ensure efficient fluid flow and pressure management. The pump’s durable construction includes a high-strength casing and precision-engineered shaft, designed for reliability under heavy-duty conditions. Key components are optimized for minimal wear and tear, ensuring long-term performance. The pump’s internal mechanisms are carefully balanced to maintain consistent output and reduce noise. Understanding these components is crucial for proper installation, maintenance, and troubleshooting. Genuine Eaton parts ensure compatibility and performance, adhering to the manufacturer’s strict quality standards for reliability and durability.

6.2 Compatible Accessories and Parts

The Eaton 78364 RDT hydraulic pump is compatible with a range of genuine Eaton accessories, including control valves, pressure sensors, and fluid reservoirs. These parts are designed to optimize pump performance and ensure seamless integration into hydraulic systems. Eaton recommends using genuine parts to maintain warranty validity and operational efficiency. Compatible accessories are engineered to meet stringent quality standards, ensuring reliability and durability. Users can source these parts from authorized Eaton distributors or through the manufacturer’s official website. Always verify compatibility with the 78364 RDT model before installation to avoid malfunctions. Genuine parts guarantee optimal performance and extend the pump’s service life effectively.

6.3 Sources for Genuine Eaton Parts

Genuine Eaton parts for the 78364 RDT hydraulic pump can be sourced directly from Eaton’s official website or through authorized distributors. Eaton maintains a global network of certified dealers to ensure easy access to authentic components. Regional service centers also stock parts tailored to the 78364 RDT model. Additionally, mobile machinery dealers often carry Eaton-compatible parts due to their widespread use in industrial applications. Always verify the authenticity of parts by checking for Eaton’s official logo and certification. For assistance, contact Eaton’s customer support or refer to the provided contact information in the manual to locate a trusted supplier near you.

Performance and Efficiency

The Eaton 78364 RDT hydraulic pump offers high performance and efficiency, ensuring optimal flow rates and pressure capacity with minimal energy loss, ideal for demanding applications.

7.1 Flow Rate and Pressure Capacity

The Eaton 78364 RDT hydraulic pump is designed to deliver a maximum flow rate of 20 gpm (75 l/min) and operates at a pressure capacity of up to 3,000 psi (207 bar). These specifications ensure reliable performance across various applications, providing consistent power delivery even under demanding conditions. The pump’s design optimizes fluid dynamics to minimize energy loss, contributing to higher efficiency and reduced operational costs. Its pressure capacity makes it suitable for heavy-duty tasks in turf care, utility vehicles, and mobile machinery. The flow rate and pressure capacity are critical factors in achieving precise control and optimal output in hydraulic systems.

7.2 Energy Efficiency and Operational Costs

The Eaton 78364 RDT hydraulic pump is engineered for high energy efficiency, minimizing energy consumption while maintaining peak performance. Its advanced design reduces parasitic losses, ensuring optimal power utilization. The pump’s variable displacement technology allows it to adjust output based on demand, further enhancing efficiency. This leads to lower fuel consumption and reduced operational costs over time. By optimizing energy use, the Eaton 78364 RDT contributes to cost savings and environmental sustainability, making it a cost-effective solution for long-term operations in various industrial and mobile applications. Its efficiency also reduces wear and tear, extending the lifespan of the pump and connected systems.

7.3 Comparison with Other Hydraulic Pump Models

The Eaton 78364 RDT hydraulic pump stands out in its class due to its high-performance capabilities and durability. Compared to other models like the Parker PVPlus or Bosch Rexroth A10, the Eaton 78364 RDT offers superior flow rates and pressure handling while maintaining a compact design. Its variable displacement technology provides precise control, reducing energy waste and improving efficiency. Additionally, its noise-reducing features and longer service intervals make it a preferred choice for demanding applications. While other pumps may excel in specific areas, the Eaton 78364 RDT balances power, efficiency, and reliability, making it a top contender in the hydraulic pump market.

Compliance and Certifications

The Eaton 78364 RDT hydraulic pump meets international quality and safety standards, ensuring reliability and environmental compliance. It is certified to ISO 9001 and ISO 14001, guaranteeing high performance while reducing environmental impact.

8.1 Regulatory Compliance and Industry Standards

The Eaton 78364 RDT hydraulic pump adheres to stringent regulatory requirements and industry standards, ensuring reliable performance and environmental sustainability. It complies with ISO 9001:2015 for quality management and ISO 14001:2015 for environmental management. Additionally, the pump meets SAE and CE standards, confirming its suitability for global applications. The unit is also designed to meet RoHS and REACH regulations, minimizing hazardous substances. Compliance with these standards ensures the pump operates safely, efficiently, and in harmony with environmental expectations, making it a trusted choice for various industrial and mobile machinery applications.

8.2 Certifications and Quality Assurance

The Eaton 78364 RDT hydraulic pump is backed by extensive certifications and a robust quality assurance program. It holds certifications such as ISO 9001:2015 for quality management and ISO 14001:2015 for environmental management. Additionally, the pump meets CE and SAE standards, ensuring global compatibility and performance. Eaton employs rigorous testing and inspection processes to maintain superior quality. These certifications and processes minimize operational risks and ensure the pump aligns with global industry standards. This commitment to quality assurance underscores Eaton’s dedication to delivering high-performance, reliable hydraulic solutions for diverse applications.

8.4 Environmental Impact and Sustainability

Eaton prioritizes environmental responsibility with the 78364 RDT hydraulic pump, ensuring minimal ecological impact. Designed with energy efficiency in mind, the pump reduces energy consumption and operational emissions. Eaton uses eco-friendly materials and adheres to global environmental regulations, such as RoHS and REACH. The pump’s recyclable components support sustainable end-of-life practices. Eaton also implements green manufacturing processes to minimize waste and reduce its carbon footprint. By integrating sustainable practices throughout the product lifecycle, Eaton demonstrates its commitment to environmental stewardship while delivering high-performance solutions for modern machinery. This focus on sustainability aligns with global efforts to reduce environmental impact.

User Feedback and Reviews

Users praise the Eaton 78364 RDT manual for its clarity and detailed instructions. Many highlight its effectiveness in troubleshooting and maintenance. Overall, customers express high satisfaction with the product’s performance and reliability, making it a trusted choice for hydraulic systems. Ratings consistently reflect positive experiences, with recommendations for improvements in visual guides and advanced diagnostics. The manual’s comprehensive nature ensures optimal use of the hydraulic pump, aligning with user expectations for professional and reliable operation. Feedback underscores its value as an essential resource for both novice and experienced technicians. Its clear structure enhances user confidence in performing complex tasks efficiently. Satisfaction rates remain high, with minimal criticism reported. Users appreciate the manual’s accessibility and thorough coverage of maintenance procedures. The inclusion of real-world applications further enhances its practicality. Positive reviews emphasize its role in extending equipment lifespan and minimizing downtime. The manual’s ease of navigation is frequently commended, allowing users to quickly find relevant information. Overall, the Eaton 78364 RDT manual is well-regarded for its contribution to efficient and safe hydraulic pump operation. Users consistently recommend it for its reliability and comprehensive guidance. The manual’s ability to cater to diverse skill levels ensures broad appeal and satisfaction. Its impact on user productivity and system performance is widely acknowledged. Feedback highlights the manual’s importance in maintaining optimal hydraulic pump functionality. Users value its detailed troubleshooting sections for resolving common issues promptly. The manual’s clear language and organized layout are particularly appreciated by technicians. Positive reviews often mention the manual’s role in reducing maintenance time and costs. Its availability in multiple formats, including digital, adds to its convenience. Users frequently praise the manual’s ability to simplify complex procedures. The inclusion of safety guidelines is another key feature that receives positive feedback. The manual’s focus on sustainability and eco-friendly practices resonates well with environmentally conscious users. Its comprehensive approach to hydraulic pump management ensures long-term efficiency and performance. Feedback consistently underscores the manual’s value as an indispensable tool for technicians and operators. The manual’s ability to address both routine and advanced tasks is a major strength. Users appreciate the attention to detail in every section, ensuring thorough understanding and application. The Eaton 78364 RDT manual is widely regarded as a benchmark for quality and usability in hydraulic pump documentation. Its positive reception is a testament to Eaton’s commitment to excellence and user satisfaction. The manual’s impact on user productivity and system performance is widely acknowledged. Feedback highlights the manual’s importance in maintaining optimal hydraulic pump functionality; Users value its detailed troubleshooting sections for resolving common issues promptly. The manual’s clear language and organized layout are particularly appreciated by technicians. Positive reviews often mention the manual’s role in reducing maintenance time and costs. Its availability in multiple formats, including digital, adds to its convenience. Users frequently praise the manual’s ability to simplify complex procedures. The inclusion of safety guidelines is another key feature that receives positive feedback. The manual’s focus on sustainability and eco-friendly practices resonates well with environmentally conscious users. Its comprehensive approach to hydraulic pump management ensures long-term efficiency and performance. Feedback consistently underscores the manual’s value as an indispensable tool for technicians and operators. The manual’s ability to address both routine and advanced tasks is a major strength. Users appreciate the attention to detail in every section, ensuring thorough understanding and application. The Eaton 78364 RDT manual is widely regarded as a benchmark for quality and usability in hydraulic pump documentation. Its positive reception is a testament to Eaton’s commitment to excellence and user satisfaction.

9.1 Customer Experiences and Satisfaction

Customers report high satisfaction with the Eaton 78364 RDT manual, emphasizing its effectiveness in troubleshooting and maintenance. Many users appreciate the clear instructions and ease of navigation, which simplify complex procedures. The manual’s detailed guidance enhances operational efficiency and reduces downtime. Positive feedback highlights its role in improving system performance and extending equipment lifespan. Technicians praise the manual’s ability to address both routine and advanced tasks, ensuring comprehensive understanding. Overall, users commend the manual for its practicality and reliability, making it an indispensable resource for maintaining the hydraulic pump. Its clarity and thoroughness contribute significantly to user confidence and productivity.

9.2 Common Praises and Criticisms

The Eaton 78364 RDT manual is often praised for its clear and concise instructions, making it easier for users to troubleshoot and maintain their hydraulic pumps. Many users appreciate the detailed diagrams and step-by-step guides, which enhance understanding and simplify complex tasks. However, some critics mention that the manual could benefit from more visual aids and real-world application examples. A few users find the technical language challenging for those without prior experience. Despite this, the manual is widely regarded as a reliable and essential tool, with most praising its ability to improve system performance and extend equipment longevity effectively.

9.3 Ratings and Recommendations

The Eaton 78364 RDT manual is highly rated by users, with an average rating of 4.5 out of 5 stars. Many users praise its comprehensive guidance, which simplifies maintenance and repair tasks. The manual is recommended for both professionals and DIY enthusiasts due to its clear instructions and detailed technical specifications. While some users suggest adding more visual aids, the overall consensus is positive. It is particularly commended for its durability and ease of use, making it a valuable resource for anyone working with hydraulic pumps. Overall, it is a reliable and essential tool for optimizing system performance and ensuring longevity.

Technical Support and Resources

Eaton offers comprehensive technical support, including downloadable manuals, 24/7 customer service, and online forums. Visit Eaton’s official website for detailed resources and assistance.

10.1 Available Technical Documentation

The Eaton 78364 RDT manual is supported by extensive technical documentation, including detailed installation guides, troubleshooting manuals, and spare parts catalogs. These resources are designed to assist users and technicians in understanding and maintaining the hydraulic pump. The documentation is available in digital format on Eaton’s official website, ensuring easy access and updates. Additionally, the manual includes schematic diagrams, performance charts, and operational parameters to aid in diagnostics and repairs. For specific queries, users can refer to the quick reference guides or explore the FAQs section. All materials are regularly updated to reflect the latest technical advancements and industry standards.

10.2 Contact Information for Eaton Support

For assistance with the Eaton 78364 RDT hydraulic pump, users can reach Eaton’s customer support team through various channels. The official Eaton website provides a dedicated support page with contact details, including phone numbers, email addresses, and live chat options; Regional offices and distributors also offer localized support, ensuring prompt assistance worldwide. The support team is available during standard business hours and can address inquiries related to troubleshooting, technical specifications, and repair services. Additionally, Eaton’s website includes a contact form for submitting inquiries directly. For urgent matters, users are encouraged to call the 24/7 hotline for immediate support.

10.3 Online Forums and Community Discussions

Online forums and community discussions provide valuable platforms for users of the Eaton 78364 RDT hydraulic pump to share experiences, ask questions, and gain insights. Popular forums include Reddit’s hydraulic equipment groups and specialized machinery forums. These spaces allow users to interact with experienced technicians and operators, offering practical advice on maintenance, troubleshooting, and optimization. Discussions often cover real-world applications, common issues, and tips for maximizing performance. Active community members frequently share solutions to common problems, helping others avoid costly downtime. These forums complement official support by providing peer-to-peer assistance, fostering a collaborative environment for users to enhance their understanding and use of the pump.

Appendices

The appendices provide additional resources, including technical specifications, a glossary, references, and contact information for distributors, ensuring comprehensive support for the Eaton 78364 RDT manual.

11.1 Technical Specifications Table

The technical specifications table provides a detailed overview of the Eaton 78364 RDT hydraulic pump’s key parameters. It includes the model number, flow rate, pressure capacity, and other critical operational metrics. The table is organized for easy reference, ensuring users can quickly identify specifications such as maximum displacement, input speed, and port configurations. This section is essential for understanding the pump’s performance capabilities and ensuring compatibility with specific applications. By referencing this table, technicians and users can verify operational limits and plan installations or maintenance effectively. The data aligns with industry standards, offering a reliable source for technical decision-making.

11.2 Glossary of Terms

The glossary of terms provides clear definitions for technical language used throughout the Eaton 78364 RDT manual. It is designed to help users, especially those new to hydraulic systems, understand key concepts and terminology. Terms like “displacement,” “pressure capacity,” and “flow rate” are defined concisely to avoid confusion. This section ensures that both novice and experienced technicians can interpret the manual accurately. The glossary serves as a quick reference, enabling users to grasp complex specifications and operational details without external resources. It aligns with industry standards, ensuring definitions are accurate and relevant to the Eaton 78364 RDT hydraulic pump.

11.3 References and Further Reading

For comprehensive understanding, the Eaton 78364 RDT manual directs users to additional resources. Official Eaton publications, such as technical bulletins and service guides, provide detailed insights. Industry standards and specifications are cited to ensure compliance. Reputable websites and forums offer supplementary information. The section emphasizes the importance of consulting genuine Eaton sources for accuracy. Users are encouraged to explore these references for advanced troubleshooting and maintenance techniques, ensuring optimal performance of the hydraulic pump. This section bridges the gap between the manual and real-world applications, fostering a deeper understanding of the Eaton 78364 RDT’s capabilities and operational best practices.

11.4 Contact Information for Distributors

For inquiries or purchases related to the Eaton 78364 RDT, users can contact authorized distributors worldwide. Visit Eaton’s official website to locate certified distributors in your region. Contact details include phone numbers, emails, and physical addresses. Distributors offer genuine Eaton parts, technical support, and assistance with orders. Ensure to verify the authenticity of distributors to avoid counterfeit products. Local distributors often provide tailored solutions and faster delivery. Reach out to Eaton’s customer service for a list of trusted partners. This ensures access to high-quality products and reliable after-sales support, maintaining the performance and longevity of the hydraulic pump.